Difference between revisions of "Manual Servo"

| Line 59: | Line 59: | ||

*Install all .1uf ceramic capacitors (C1,C5,C6,C7,C10,C11,C12,C13,C14) | *Install all .1uf ceramic capacitors (C1,C5,C6,C7,C10,C11,C12,C13,C14) | ||

*Install the 10uf ceramic capacitor (C3) | *Install the 10uf ceramic capacitor (C3) | ||

| + | (Please note that your component color and/or size may not exactly match what you see in these photos. Please verify component characteristics before installing.) | ||

[[Image:Servo2.jpg|300px|Thumb]] | [[Image:Servo2.jpg|300px|Thumb]] | ||

| + | |||

---- | ---- | ||

Revision as of 20:48, 9 November 2011

Notice

The PIC does NOT come pre-programmed from Microchip or any supplier. If you do not have a programmer then please see the PIC Programming Wiki page for a list of DLA users who can program the PIC for you. If you are programming the PIC yourself, download the hex file from the Wiki and program the PIC chip using the appropriate steps for your programmer setup. Check out this post for a helpful pdf on PIC programming. Some helpful tips on PIC programming can also be found on this You Tube video.

Introduction

This is the manual to guide you through the build process of the DMX Servo Controller.

WARNING! This device has been designed for personal use as a means of education and entertainment. As such it is not rated, tested, or approved for use in commercial environments and such use is forbidden by the designer. Improper use of this equipment could be hazardous to life and property and the suitability of use is your responsibility. I assume no responsibility in the use or operation of this equipment or for the accuracy of any information made on part of itself. This device has been designed for my use and my use only. This is simply an explanation of how I built my own personal dimmers for informational purposes. I make no warranties written or otherwise to it. It should be considered an experimental device with possible unknown characteristics.

Before you start the build, use the Mouser Direct link on the wiki page to verify you have the correct parts and quantity of parts before we go any further. Please use static electricity precautions in the handling of these parts (ground straps, etc.). If you are not familiar with them please research on the Internet prior to handling them. You can damage your parts with improper handling!

Ensure you are using the correct DMX Servo Controller PCB for this build.

Preparing to Build

The next thing we want is to make sure you are up to speed on soldering and electrostatic protection of the components in your kit. If you are not an experienced printed circuit builder, visit the Curious Inventor website and review the How to Solder guides just below the video. The video on soldering correctly at the top of the page is extremely good to watch even if you are experienced at soldering.

Another issue you must be aware of is that some electronic components can be damaged easily by electrostatic charges that can build up in you or your equipment. We have all been shocked by walking on carpet and grabbing a doorknob. This is electrostatic charge in action. It takes much less than this to hurt some of the parts. If you are unfamiliar with procedures to protect from this, please use the Internet to research it before opening your parts up. You can damage your parts with improper handling!

You will need a few tools build the DMX Servo Controller. You will need a good soldering iron. I cannot stress enough that a good soldering iron makes a big difference in these projects. The little 15w cheap irons are more apt to hurt your parts by taking too long to get the parts up to soldering temperature than a good iron which can bring it up to temp very fast. Remember, damage is a factor more in how long you keep the part hot than it is how hot you get it (within reasonable soldering temperatures). A good soldering iron is reasonable: You can purchase one for $30 to $60. Most any product that calls itself a soldering station that includes a temperature control separate from the iron itself will more than likely be fine, but make sure it is rated for more than 15 watts. I use a cheap Weller like this: Weller Soldering Station. It works fine and is very inexpensive. I even saw this model on sale at Sears. Radio Shack has a very nice looking digital model on sale but be careful: it does not allow you to replace the tip. Tips are a part that wear out and need to replace them from time to time. While we are on the topic of tips, get some. I recommend you get the smaller chisel shape as this works very well for all-around board building.

You need solder, so buy some. I recommend .032 size as the larger sizes tend to cause you to put too much solder on. How much? Go ahead and get a 1 lb spool as it’s cheaper in large volume and you will go through it faster than you think. Make sure you are getting rosin core for electronics; they make some solder for plumbing that has acid as the core and this is a bad mistake to make.

You need some work area to work with good lighting. Do not attempt to solder circuit boards in poorly lighted areas. If you wear reading glasses, go get them: you will want them I promise you. I also recommend getting a helping hands tool similar to this: Helping Hands Tool.

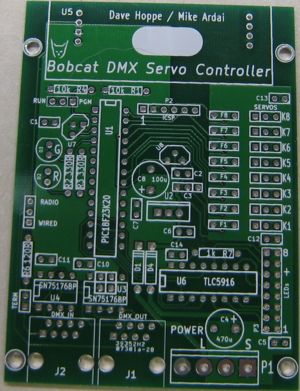

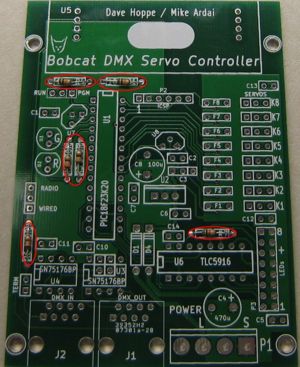

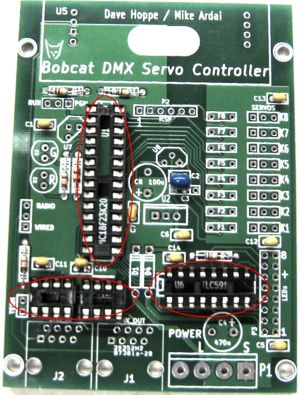

PCB Assembly

If this is your first build we have laid out the order for soldering the components to the board in a step by step procedure for you to follow. Components are outlined in red for each step as they are soldered to the board. Ensure that you orient the parts as shown on the PCB and in the assembly pictures.

- Install the R1 and R4 (10k ohm - brown,black,orange) resistors at upper left.

- Install the R2 and R3 (330 ohm - orange,orange,brown) resistors at middle left.

- Install the R6 (120 ohm - brown,red,brown) resistor at lower left.

- Install the R7 (1k ohm - brown,black,red) resistor at lower right.

(Please note that your component color and/or size may not exactly match what you see in these photos. Please verify component characteristics before installing.)

- Install all .1uf ceramic capacitors (C1,C5,C6,C7,C10,C11,C12,C13,C14)

- Install the 10uf ceramic capacitor (C3)

(Please note that your component color and/or size may not exactly match what you see in these photos. Please verify component characteristics before installing.)

- Install sockets

- Install electrolytic caps, headers and power connector

- Install LEDs, supervisory chip and regulator

- Install Diode and Ex/Rx headers