Manual EXRX

Contents

- 1 Introduction

- 2 Preparing to Build

- 3 Step 1 - Installing the RF Module

- 4 Step 2 - Installing Resistors

- 5 Step 3 - Installing Ceramic Capacitors

- 6 Step 4 - Installing LED's

- 7 Step 5 - Installing PIC Socket

- 8 Step 6 - Installing the Headers

- 9 Step 7 - Installing the Electrolytic Capacitor and Voltage Regulator

- 10 Step 8 - Installing the PIC Chip

- 11 Step 9 - Installing the Lynx Express Mating Connectors

- 12 Wireless Jumper Settings and Lynx Express Board Modifications Needed for Wireless to work

Introduction

Thank you for making the decision to build the LYNX DMX Express Receiver. I believe this decision will be one you will be very happy with.

WARNING! This device uses potentially deadly voltages in operation. If you do not feel it is within your ability to work with these voltages please stop and get assistance, or purchase ready built commercial Equipment. This Equipment has been design for personal use as a means of education and entertainment. As such it is not rated, tested, or approved for use in commercial environments and as such is forbidden by the designer. Improper use of this equipment could be hazardous to life and property and the suitability of use is your responsibility. I assume no responsibility in the use or operation of this equipment or for the accuracy of any information made on part of itself. This device has been design for my use and my use only. This is simply an explanation of how I built my own personal equipment for informational purposes. I make no warranties written or otherwise to it. It should be considered an experimental device with possible unknown characteristics.

Before we start assembly of the Module we want to do two things. First we need to take inventory and make sure we have all the components that should have come with the coop kit. Using the list on the next page verify you have the correct parts and quantity of parts before we proceed any farther. Please use static precautions in the handling of these parts. If you are not familiar in them please research on the internet prior to handling them. You can damage you parts with improper handling!

Preparing to Build

I trust you have everything you should you have.

The next thing we want is to make sure you are up to speed on soldering and electrostatic protection of the components in your kit. If you are not an experienced printed circuit builder I recommend you visit the site:

http://curiousinventor.com/guides/How_To_Solder

And check out there extremely good video on soldering correctly. Even if you are an expert it is a good video to watch.

Another issue you must be aware of is that some electronic components can be damaged easily by electrostatic charges that can build up in you or your equipment. We have all been shocked by walking on carpet and grabbing a door knob before. This is electrostatic charge in action. It takes much less than this to hurt some of our parts. If you are unfamiliar with procedures to protect from this please use the internet to research it before opening your parts up. You can damage your parts if handled wrong!

You will need a few tools that do not come with your kit to build the Transmitter. You will need a good soldering iron. I can not stress enough that a good soldering iron makes a big difference in these projects. The little 15w cheap irons are more apt to hurt your parts by taking too long to get the parts up to soldering temperature than a good iron which can bring it up to temp very fast. Remember it is more how long you keep the part hot than it is how hot you get it within reasonable soldering temperatures. A good soldering iron can be had for very reasonable amounts of money. You can purchase one for $30 to $60 dollars. Most anything that is called a soldering station where there is a temperature control separate from the iron itself will more than likely be fine but make sure it is rated for more than 15 watts. I myself use a cheap Weller like this one

http://www.amazon.com/Weller-Soldering-Station-WLC100-120V/dp/B000ICEMYA

It works fine and is very inexpensive. I even saw this model on sale at Sears. Radio shack has a very nice looking digital model on sale but be careful as it does not allow you to replace the tip. Tips are a part that wear out and need replacing from time to time. While we are on tips get some. I recommend you get the smaller chisel shape as this work very well for all around board building.

You need solder so buy some. I recommend .032 size (0.8mm or 0.7mm) as the larger sizes tend to cause you to put too much solder on. How much? Go ahead and get a 1 lb spool as it’s cheaper in large volume and you will go through it faster than you think. Make sure you are getting rosin core for electronics they make some solder for plumbing that has acid as the core this is a bad mistake to make.

You need some work area to work with good lighting. Do not attempt to solder circuit boards in poorly lighted areas. If you wear reading glasses go get them you will want them I promise you. I recommend a set of helping hands like this: http://www.radioshack.com/product/index.jsp?productId=2104639&cp=&parentPage=search or [1]

HarborFreight or [2] Amazon.com.

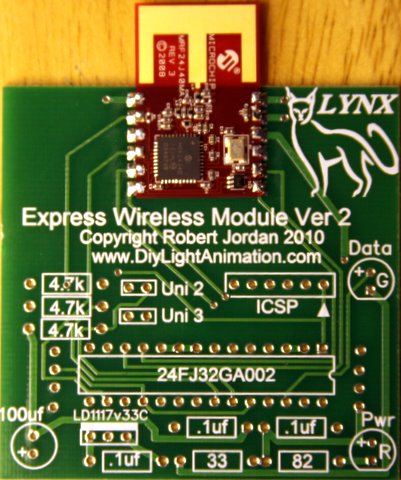

Step 1 - Installing the RF Module

OK we are ready to start assembly of the Module. I recommend you install the RF module on the PCB first. Align its pads centered on the pads of the PCB and while holding light pressure with your finger carefully on the larger black chip touch your clean soldering iron tip point into the notch of one of the corner pads of the module and after about a second to heat it touch a slight amount of solder to the top of the pad and iron tip at the same time. It will flow and wick onto the pad of the PCB and make a connection.

Now do the same at the opposite corner pad and this will lock the module in place. Now you can let go of the RF module and do the same soldering on the other pads.

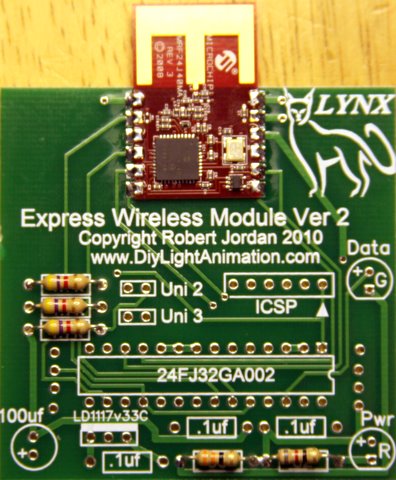

Step 2 - Installing Resistors

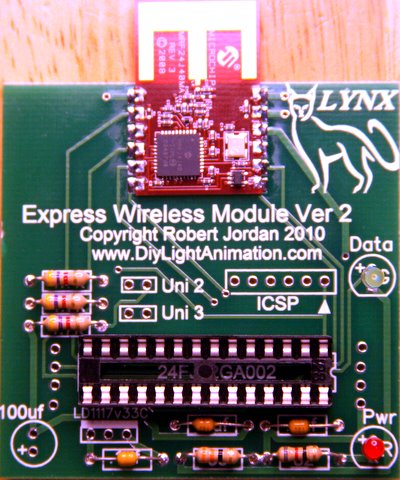

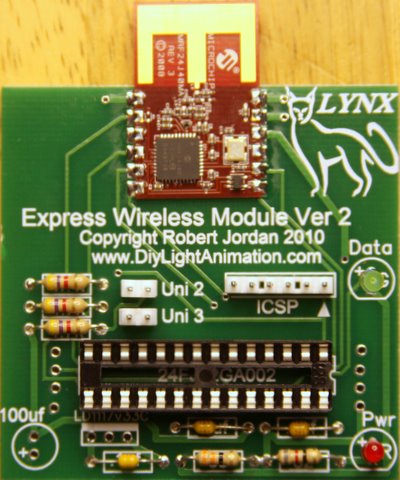

Install all five of the resistors in their proper place. Resistors do not have a wrong direction but I always put the color bands facing the same direction to make it look professional.

Install three 4.7k ohm (yellow-violet-red) resistors right together on the left side half way up the board.

Install one 33 ohm (orange-orange-black) resistor in the middle at the bottom of the board.

Install one 82 ohm (gray-red-black) resistor in the lower right corner.

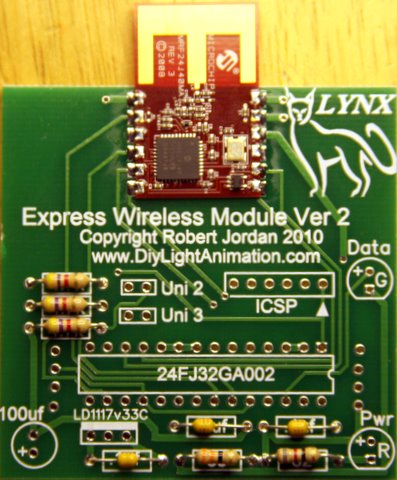

Step 3 - Installing Ceramic Capacitors

Install the three 0.1uf capacitors near the bottom of the board. There is no wrong direction for these.

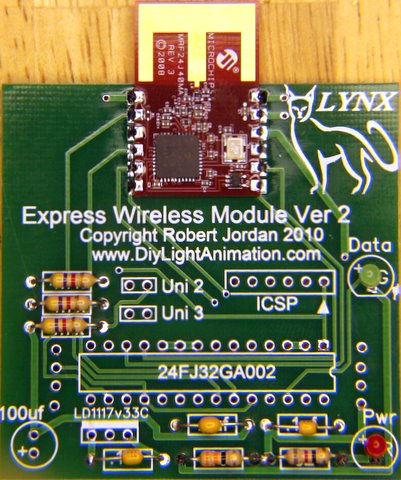

Step 4 - Installing LED's

Install the 2 LED's. The green LED goes in the upper right location labeled "Data (G)" and the red LED goes in the lower right area labeled "Pwr (R)". It is important to install the LED's oriented properly. The LED will generally have one lead that is longer than the other. This is the positive (+) lead. The LED should be installed with the longer positive lead in the hole near the "+" label on the PCB.

Step 5 - Installing PIC Socket

Install the 28 pin Socket. Line up the notch on the socket with the notched end of the drawing on the PCB and then solder all the pins.

Some sockets now come with slightly contoured pins that hold them in place in the PCB prior to soldering. If you do not have this kind of socket you will want to use a method to hold it in place while soldering. Everyone has their own way of holding the socket in. I like to turn the board over to the back and put the least amount of solder I can over one of the middle holes on one side of the socket. This allows you to put the pins of the other side of the socket through and hold the socket while pushing extremely easy. Then you heat that one hole on the back. When the solder melts the socket will drop in. remove the iron and it will cool and hold the socket in until you are done. Make sure to reheat this pin while doing the others to insure you have a good joint. Some people prefer to use tape to hold them in and some even super glue them on first and then solder. If you use tape then the painter’s masking tape is a good option as it does not leave any residue behind when it is removed. Make sure your socket is in the correct holes and that it faces the correct way and then solder the other pins in.

Step 6 - Installing the Headers

Install the two 2 pin and the one 6 pin headers. Make sure you put the small pins through the hole and point the longer pins up.

Step 7 - Installing the Electrolytic Capacitor and Voltage Regulator

Now install your 100uf cap near the bottom left. Electrolytic capacitors are polarized and must be installed in the proper direction. Rotate the capacitor slowly while watching for the markings and graphical images on the capacitor. Some electrolytic capacitors will have only the negative side marked; the symbols will appear as ovals that look like minus signs (-), indicating the negative side of the capacitor. Some capacitors will have a white or a black stripe on the negative side. In such a case, the opposite side of the electrolytic capacitor is the positive side. If you cannot find the minus sign but you are able to see a plus sign (+), then the plus sign indicates the positive side and the other is the negative side.

Make sure the positive lead is in the hole marked with the plus (+) sign.

Install the LD1117 voltage regulator making sure you have it in the correct location and turned the correct way. The metal back of the regulator should be towards the PIC chip socket (28 pin) as shown above.

Step 8 - Installing the PIC Chip

Install the PIC chip. Make sure you align the notch on the end of the PIC chip with the notch on the socket. Be careful to not bend any pins under while pushing the chip in.

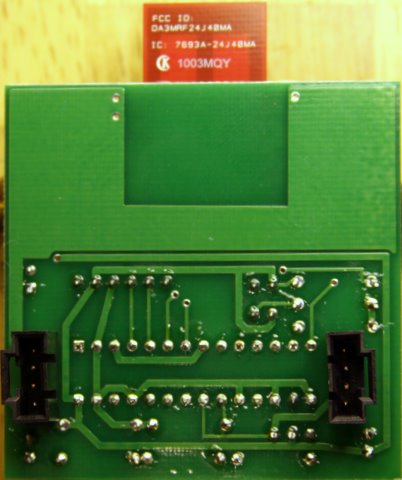

Step 9 - Installing the Lynx Express Mating Connectors

The last step is to add the connectors. The shrouded male connector goes on the module and the female socket goes on the Express PCB. The connectors are installed on the rear of the Wireless Module. Before installing them, put the male and female together. Slide them in place on the module and slide all of this onto your Express. When the assembly is square, solder the pins to the module. Flip the entire assembly (Express and Wireless module) over and solder the pins to the Lynx Express. This will align it all straight. Otherwise, if done apart it may not line up close enough to fit. The connectors fit kind of tight which is good but means they must line up correctly.

If you have several modules to assemble, we recommend that you use the one Lynx Express with female connectors attached to align the shrouded male connectors on all of the modules.

Caution: Solder all four pins on each of the connectors before removing the module from the Lynx Express.

Wireless Jumper Settings and Lynx Express Board Modifications Needed for Wireless to work

There are two jumpers on the Wireless board that allow you to choice the DMX universe. "Uni 2" and "Uni 3" select which universe the wireless is on. Each universe is 512 channels so if you have enough transmitters, you can effectively run 512 x 3 = 1536 channels. The jumpers need to be the same on both the transmitter (TX) and the Wireless Receiver (RX).

No Jumpers = Universe 1

Jumper on "Uni 2" = Universe 2

Jumper on "Uni 3" = Universe 3

The Lynx Express board needs the following changes for the Wireless Receiver to work properly:

- LE ver 2.0: Remove the RS-485 chip

- LE ver 3.0: Remove the RS-485 chip on the right side of the DMX IN RJ485 connector

- LE ver 4.0: Remove the jumper labeled "Remove for Wireless" to enable wireless mode

- LE ver 5.0: Remove the jumper labeled "Remove for Wireless" to enable wireless mode

Sit back take a deep breath you did it! Pat yourself on the back and have a cold whatever it is you enjoy.

Thank you, enjoy your Lynx Wireless Receiver

RJ

(Updates for V2 by mokeefe)