|

|

| Line 41: |

Line 41: |

| | ---- | | ---- |

| | | | |

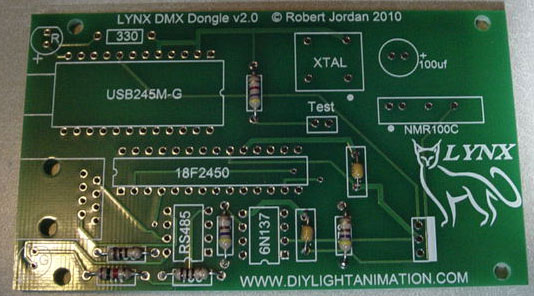

| − | <center>'''The LYNX EXPRESS Assembly Manual'''</center> | + | <center>'''The LYNX DMX Dongle '''</center> |

| − | <center>for version Ver 5 pcb</center>

| + | |

| | | | |

| | + | <center>'''Assembly Manual'''</center> |

| | | | |

| − | <center>[[Image:LEV4-Fin.jpg|600px|Thumb]]</center>

| + | [[Image:Dongle2-5.jpg|600px|Thumb]] |

| | | | |

| | | | |

| | + | ='''NOTICE'''= |

| | + | The pic does '''NOT''' come pre-programmed from Microchip or any supplier. If you don't have a programmer then please see this [http://diylightanimation.com/wiki/index.php?title=PIC_Programming wiki page] for a list of folks who can program the pic for you. |

| | | | |

| − | =='''Introduction'''==

| |

| | | | |

| | + | = '''Introduction''' = |

| | | | |

| − | Thank you for making the decision to build the LYNX EXPRESS HOLIDAY LIGHT DIMMER. I believe this decision will be one you will be very happy with. The EXPRESS is my attempt to design the best internal SSR dimmer available for the do it yourselfer like you. What you are about to assemble is the outcome of many hours of design, test and redesign of the hardware as well as the firmware that operates it. The goals for the EXPRESS were professional looks and operation, cost effective, easy to assemble for even a novice builder and DMX compatible

| |

| | | | |

| − | '''WARNING! This device uses potentially deadly voltages in operation. If you do not feel it is within your ability to work with these voltages please stop and get assistance, or purchase ready built commercial dimmers. This dimmer has been design for personal use as a means of education and entertainment. As such it is not rated, tested, or approved for use in commercial environments and as such is forbidden by the designer. Improper use of this equipment could be hazardous to life and property and the suitability of use is your responsibility. I assume no responsibility in the use or operation of this equipment or for the accuracy of any information made on part of itself. This device has been design for my use and my use only. This is simply an explanation of how I built my own personal dimmers for informational purposes. I make no warranties written or otherwise to it. It should be considered an experimental device with possible unknown characteristics. '''

| + | Thank you for making the decision to build the LYNX DMX DONGLE. I believe this decision will be one you will be very happy with. The Lynx is my attempt to design the best DMX dongle I could, at the lowest price I could, and make it available for the do-it-yourselfers like you. The goals for the dongle were professional looks and operation, cost effectiveness and ease of assembly for even a novice builder. |

| | | | |

| | + | '''WARNING! This device has been designed for personal use as a means of education and entertainment. As such it is not rated, tested, or approved for use in commercial environments and such use is forbidden by the designer. Improper use of this equipment could be hazardous to life and property and the suitability of use is your responsibility. I assume no responsibility in the use or operation of this equipment or for the accuracy of any information made on part of itself. This device has been designed for my use and my use only. This is simply an explanation of how I built my own personal dimmers for informational purposes. I make no warranties written or otherwise to it. It should be considered an experimental device with possible unknown characteristics.''' |

| | | | |

| − | Before we start assembly of the EXPRESS we want to do two things. First we need to take inventory and make sure we have all the components that should have come with the coop kit. Using the list on the next page verify you have the correct parts and quantity of parts before we proceed any further. Please use static precautions in the handling of these parts. If you are not familiar in them please research on the internet prior to handling them. '''You can damage you parts with improper handling'''!

| |

| | | | |

| − | '''''TAKE YOUR TIME BUILDING THE EXPRESS, Take care inspecting the solder joints and making sure ALL parts and chips are in the proper orientation as per the silk screen on the pcb.'''''

| + | Before we start assembly of the LYNX DMX DONGLE, use the list on the next page to verify you have the correct parts and quantity of parts before we go any further. Please use static electricity precautions in the handling of these parts (ground straps, etc.). If you are not familiar with them please research on the Internet prior to handling them. '''You can damage your parts with improper handling'''! |

| | | | |

| − | =='''Parts List'''==

| + | |

| | + | ='''Parts List'''= |

| | | | |

| | {| class="prettytable" | | {| class="prettytable" |

| − | | '''Mouser Part #''' | + | | '''QTY''' |

| − | | '''Description''' | + | | '''Mouser #''' |

| − | | '''Quantity''' | + | | '''Description of Component''' |

| | + | | |

| | + | | '''Needed in Step''' |

| | | | |

| | |- | | |- |

| − | |291-180-RC | + | | 2 |

| − | |1/4W 5% Carbon Film Resistors 180ohms 0.05

| + | | 291-100-RC |

| − | | <div align="right">17</div>

| + | | 100 ohms 1/4W Resistors |

| − | | + | | |

| − | |-

| + | | 1 |

| − | |291-1k-RC | + | |

| − | |1/4W 5% Carbon Film Resistors 1Kohms 0.05 | + | |

| − | | <div align="right">1</div> | + | |

| − | | + | |

| − | |-

| + | |

| − | |660-CF1/2CT52R473J

| + | |

| − | |1/2W 5% Carbon Film Resistors 47k ohms | + | |

| − | | <div align="right">16</div>

| + | |

| | | | |

| | |- | | |- |

| − | |604-WP7104GD | + | | 2 |

| − | |Kingbright LED Std GREEN DIFFUSED | + | | 581-SA115C104KAR |

| − | | <div align="right">19</div> | + | | 50 volts 0.1uF Capacitors |

| | + | | |

| | + | | 1 |

| | | | |

| | |- | | |- |

| − | |291-330-RC | + | | 2 |

| − | |1/4W 5% Carbon Film Resistors 330ohms 0.05 | + | | 291-470-RC |

| − | | <div align="right">1</div> | + | | 470 ohms 1/4W Resistors |

| | + | | |

| | + | | 2 |

| | | | |

| | |- | | |- |

| − | |571-1-390261-1 | + | | 2 |

| − | |IC Sockets 6P ECONOMY TIN | + | | 571-1-390261-2 |

| − | | <div align="right">17</div> | + | | 8 Pin Sockets |

| | + | | |

| | + | | 3 |

| | | | |

| | |- | | |- |

| − | |511-BTA06-600S | + | | 1 |

| − | |Triacs 6 Amp 600 Volt | + | | 571-1-390261-9 |

| − | | <div align="right">16</div> | + | | 28 Pin Socket |

| | + | | |

| | + | | 3 |

| | | | |

| | |- | | |- |

| − | |859-MOC3023 | + | | 1 |

| − | |Optocomponents Optocoupler TRIAC | + | | 815-ACH-40-EK |

| − | | <div align="right">16</div> | + | | Crystal Clock Oscillator |

| | + | | |

| | + | | 3 |

| | | | |

| | |- | | |- |

| − | |576-01020071H | + | | 1 |

| − | |Fuseholders, Blocks, and Clips 3AG PC Clip | + | | 580-MER1S0505SC |

| − | | <div align="right">4</div> | + | | DC/DC Converters & Regulators 1W 5Vin 5Vout 200mA 1kVDC Isolated SIP |

| | + | | |

| | + | | 3 |

| | | | |

| | |- | | |- |

| − | |291-4.7K-RC | + | | 1 |

| − | |1/4W 5% Carbon Film Resistors 4.7Kohms 0.05 | + | | 140-XRL25V100-RC |

| − | | <div align="right">3</div> | + | | 100uf Capacitor |

| | + | | |

| | + | | 3 |

| | | | |

| | |- | | |- |

| − | |571-1-390261-3 | + | | 1 |

| − | |IC Sockets 14P ECONOMY TIN | + | | 512-FQP27P06 |

| − | | <div align="right">3</div> | + | | MOSFET |

| | + | | |

| | + | | 3 |

| | | | |

| | |- | | |- |

| − | |571-5520260-4 | + | | 1 |

| − | |Modular Jacks 8P8C TOP ENTRY | + | | 626-DLP-USB245M-G |

| − | | <div align="right">3</div> | + | | USB Adapter |

| | + | | |

| | + | | 4 |

| | | | |

| | |- | | |- |

| − | |581-SA115C104KAR | + | | 1 |

| − | |Multilayer Ceramic Capacitors (MLCC) - Leaded 50volts 0.1uF 10% X7R | + | | 571-55202514 |

| − | | <div align="right">3</div> | + | | RJ45 Modular Jack |

| | + | | |

| | + | | 4 |

| | | | |

| | |- | | |- |

| − | |604-SA04-11GWA | + | | 1 |

| − | |LED Displays .4" GREEN | + | | 511-ST485BN |

| − | | <div align="right">3</div> | + | | RS-485 Interface Chip |

| | + | | |

| | + | | 5 |

| | | | |

| | |- | | |- |

| − | |140-XRL25V100-RC | + | | 1 |

| − | |Radial Electrolytic Capacitors 25V 100uF 20% | + | | 630-6N137-000E |

| − | | <div align="right">2</div> | + | | Optocoupler Chip |

| | + | | |

| | + | | 5 |

| | | | |

| | |- | | |- |

| − | |294-15K-RC | + | | 1 |

| − | |1W 5% Carbon Film Resistors 15Kohms 5%

| + | | 579-PIC18F2450-I/SP |

| − | | <div align="right">2</div>

| + | | 16K Microcontroller Chip |

| − | | + | | |

| − | |-

| + | | 5 |

| − | |511-ST485BN

| + | |

| − | |5V RS-485 Interfaces Hi-Spd Lo Pwr Trans

| + | |

| − | | <div align="right">2</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |532-7128DG

| + | |

| − | |Heatsink TO-220, VERT 19.2 TR

| + | |

| − | | <div align="right">2</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |571-1-390261-2

| + | |

| − | |IC Sockets 8P ECONOMY TIN

| + | |

| − | | <div align="right">2</div>

| + | |

| − | | + | |

| − | |- | + | |

| − | |576-0314020.HXP

| + | |

| − | |Fuses - Axial Lead, Radial Lead, and Cartridge 250V 20A Fast Acting

| + | |

| − | | <div align="right">2</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |651-1714971

| + | |

| − | |PCB Terminal Blocks 2P 9.52mm 90DEG

| + | |

| − | | <div align="right">2</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |651-1935307

| + | |

| − | |PCB Terminal Blocks PT 1.5/16-5.0-H

| + | |

| − | | <div align="right">2</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |688-SPPH430200

| + | |

| − | |Push Switches VERT MOMENTRY 2 POLE

| + | |

| − | | <div align="right">3</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |140-XRL25V4700-RC

| + | |

| − | |Radial Electrolytic Capacitors 25V 4700uF 20%

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |271-120-RC

| + | |

| − | |1/4W 1% Metal Film Resistors 120ohms 1% 50PPM

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |291-2K-RC

| + | |

| − | |1/4W 5% Carbon Film Resistors 2Kohms 0.05

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |511-L7805ABV

| + | |

| − | |Linear Regulators - Standard 5.0V 1.0A Positive

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |538-22-03-2021

| + | |

| − | |.100 K.K. Connectors VERT PCB HDR 2P TIN PLATING

| + | |

| − | | <div align="right">2</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |538-22-03-2061

| + | |

| − | |.100 K.K. Connectors VERT PCB HDR 6P TIN PLATING

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |571-1-390261-9

| + | |

| − | |IC Sockets 28P ECONOMY TIN SKT

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |571-1-390262-1

| + | |

| − | |IC Sockets 24P ECONOMY TIN

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |579-PIC24FJ32GA002SP

| + | |

| − | |PICmicro PIC24FJxxx Flash MCUs 32KB 8192 bytes 16MIPS 21 I/O

| + | |

| − | | <div align="right">1</div> | + | |

| − | | + | |

| − | |- | + | |

| − | |511-LD1117V33C | + | |

| − | |Low Dropout (LDO) Regulators 3.3V 0.8A Positive

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |625-W005G-E4

| + | |

| − | |Bridge Rectifiers 1.5 Amp 50 Volt

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |649-65474-002LF

| + | |

| − | |Bergcon Connectors SHUNT TIN

| + | |

| − | | <div align="right">2</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |771-SAA1064PN

| + | |

| − | |Drivers - LED LED DRVR 4DGT W/I2C

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |782-H11AA1

| + | |

| − | |Optocouplers Bi-Directional Input

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |80-C315C272K1R

| + | |

| − | |Conformally Coated Radial Ceramic Capacitors 100volts 2700pF 10% X7R

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |838-3FD-312

| + | |

| − | |Power Transformers 12.6VCT@.2A 6.3V@.4A Dual Primary

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |HeatSink

| + | |

| − | |RJ HeatSink

| + | |

| − | | <div align="right">1</div>

| + | |

| − | | + | |

| − | |-

| + | |

| − | |Lynx Express PCB

| + | |

| − | |RJ Lynx Express PCB

| + | |

| − | | <div align="right">1</div>

| + | |

| | | | |

| | |} | | |} |

| | | | |

| | + | Case (Choose Gray and put in the comments of the order "Make Sure it has the PCB bosses" ) http://www.polycase.com/item/lp-35p.html |

| | | | |

| − | Case (Coax Demarcation Enclosures 12.25 X 12 X 5.25) http://www.yourbroadbandstore.com/product.php?pid=706098

| + | ='''Preparing to Build'''= |

| | | | |

| − | Extra Items needed to finish one Lynx Express but '''NOT included''' in the kit:

| |

| − | * Electric power cords(2) and channel controlled cords (16)

| |

| − | * Heat Sink Compound (Radio Shack has this) @ $3.00

| |

| − | * #8 Sheet Metal Screws 1/2 inch long (4)

| |

| | | | |

| − | =='''Preparing to Build'''==

| + | The next thing we want is to make sure you are up to speed on soldering and electrostatic protection of the components in your kit. If you are not an experienced printed circuit builder, visit the site: [http://curiousinventor.com/guides/How_To_Solder http://curiousinventor.com/guides/How_To_Solder] |

| − | | + | |

| − | | + | |

| − | I trust you found everything in your order but should you have any issue just contact your coop manager and they will take care of it.

| + | |

| − | | + | |

| − | | + | |

| − | The next thing we want is to make sure you are up to speed on soldering and electrostatic protection of the components in your kit. If you are not an experienced printed circuit builder I recommend you visit the site: | + | |

| − | | + | |

| − | [http://curiousinventor.com/guides/How_To_Solder http://curiousinventor.com/guides/How_To_Solder] | + | |

| | | | |

| | And check out there extremely good video on soldering correctly. Even if you are an expert it is a good video to watch. | | And check out there extremely good video on soldering correctly. Even if you are an expert it is a good video to watch. |

| | | | |

| | | | |

| − | Another issue you must be aware of is that some electronic components can be damaged easily by electrostatic charges that can build up in you or your equipment. We have all been shocked by walking on carpet and grabbing a door knob before. This is electrostatic charge in action. It takes much less than this to hurt some of our parts. If you are unfamiliar with procedures to protect from this please use the internet to research it before opening your parts up. '''You can damage you parts with improper handling!''' | + | Another issue you must be aware of is that some electronic components can be damaged easily by electrostatic charges that can build up in you or your equipment. We have all been shocked by walking on carpet and grabbing a doorknob. This is electrostatic charge in action. It takes much less than this to hurt some of the parts. If you are unfamiliar with procedures to protect from this, please use the Internet to research it before opening your parts up. '''You can damage your parts with improper handling!''' |

| − | | + | |

| − | | + | |

| − | You will need a few tools that do not come with your kit to build the EXPRESS. You will need a good soldering iron. I can not stress enough that a good soldering iron makes a big difference in these projects. The little 15w cheap irons are more apt to hurt your parts by taking too long to get the parts up to soldering temperature than a good iron which can bring it up to temp very fast. Remember it is more how long you keep the part hot than it is how hot you get it within reasonable soldering temperatures. A good soldering iron can be had for very reasonable amounts of money. You can purchase one for $30 to $60 dollars. Most anything that is called a soldering station where there is a temperature control separate from the iron itself will more than likely be fine but make sure it is rated for more than 15 watts. I myself use a cheap Weller like this one

| + | |

| − | | + | |

| − | | + | |

| − | '''Solder Stations:'''

| + | |

| − | *[http://www.amazon.com/Weller-Soldering-Station-WLC100-120V/dp/B000ICEMYA http://www.amazon.com/Weller-Soldering-Station-WLC100-120V/dp/B000ICEMYA]Weller WLC100

| + | |

| − | | + | |

| − | | + | |

| − | It works fine and is very inexpensive. I even saw this model on sale at Sears. Radio Shack has a very nice looking Digital Soldering Station (Model #64-053) for sale but you can't order the tips directly from Radio Shack. You need to order them directly from the manufacturer at [http://www.madelltech.com/nozzles-tips.html Madell Tech's website]. A forum member uses this iron at his business and on the road and it's been rock solid.

| + | |

| − | | + | |

| − | | + | |

| − | Another recommended Solder Station is the MPJA 302A is has a digital temperature readout

| + | |

| − | *[http://www.mpja.com/prodinfo.asp?number=15141+TL http://www.mpja.com/prodinfo.asp?number=15141+TL]MPJA Model 302A

| + | |

| − | | + | |

| − | | + | |

| − | What ever you get make sure and get 4 - 5 extra tips for it. It is an opinion thing but I prefer and find most prefer Chisel tips. get a couple .8 and a few 1.6 to see which you like and then you are ready to go. The tips do wear out and need replacement from time to time. I can build maybe 4 to 8 big controllers (FS, Etc) with a single tip but when you are learning you will use them up faster.

| + | |

| − | | + | |

| − | | + | |

| − | You need solder so buy some. I recommend .032 size (0.8mm or 0.7mm) as the larger sizes tend to cause you to put too much solder on. How much? Go ahead and get a 1 lb spool as it’s cheaper in large volume and you will go through it faster than you think. Make sure you are getting rosin core for electronics they make some solder for plumbing that has acid as the core this is a bad mistake to make.

| + | |

| − | | + | |

| − | | + | |

| − | You need some work area to work with good lighting. Do not attempt to solder circuit boards in poorly lighted areas. If you wear reading glasses go get them you will want them I promise you. I recommend a set of helping hands like this: [http://www.radioshack.com/product/index.jsp?productId=2104639&cp=&parentPage=search http://www.radioshack.com/product/index.jsp?productId=2104639&cp=&parentPage=search]

| + | |

| − | | + | |

| − | | + | |

| − | '''''Note: If you are planning to run your Express as a single power input unit and limit it to 20 amps max total, then please see Appendix A on the modification before you begin.

| + | |

| − | | + | |

| − | '''''Note: For 240VAC operation, see Appendix B at the end of this Manual before you begin.'''''

| + | |

| − | | + | |

| − | =='''Step 1''' {Resistors and some Capacitors}==

| + | |

| − | | + | |

| − | | + | |

| − | <center>[[Image:LEv5-1.jpg|600px|Thumb]]</center>

| + | |

| − | | + | |

| − | Express board after the resistors and capacitors are installed

| + | |

| − | | + | |

| − | | + | |

| − | Ok we are ready to start assembly of the EXPRESS. Begin by installing all of the resistors in their proper place.

| + | |

| − | Resistors do not have a wrong direction but I always put the color bands the same direction to make it look professional. All soldering takes place on the bottom or (back) of the board away from the markings. Remember that when you turn the board over to the back every thing reverses on you.

| + | |

| − | | + | |

| − | *There are 16 180 ohm resistors (Brown, Gray, Brown, Gold) along the bottom of the board.

| + | |

| − | | + | |

| − | *Above and to the left there is a place for one 330 ohm (Orange, Orange, Brown, Gold) and one 180 ohm resistors(Good Power indicators 5v and 3.3v) and one 1K ohm resistor for DMX data indicator.

| + | |

| − | | + | |

| − | *Install the three 4.7K ohm resistors (Yellow, Violet, Red, Gold) in the marked locations at the top of the board.

| + | |

| − | | + | |

| − | *Install the 120 ohm resistor (Brown, Red, Brown, Black) in the correct location at the top of the pcb.

| + | |

| − | | + | |

| − | *Install the two 15K ohm resistors (Brown, Green, Orange, Gold) 1 watt in their location on the left side above the fuse. These are larger resistors than the rest.

| + | |

| − | | + | |

| − | *Install the 2k ohm resistor (Red, Black, Red, Gold) in its location just above these.

| + | |

| − | | + | |

| − | *Now find the location for the three .1uf caps and the one 2700pf cap and install them. There is no wrong direction for these.

| + | |

| − | | + | |

| − | *At the bottom of the pcb for 16 additional resistors.

| + | |

| − | **If using 120 volts, Install 16 47k ohm 1/2 watt resistor in these locations at this time as snubber resistors. Their job is to help with LED light users prevent the random flicker some Led light strings can have when using them with light dimmers.

| + | |

| − | | + | |

| − | **If you are using 240 volts, you must either not install these or install different resistors. To install them with 240 volt they Must be 100k ohm 1/2 watt and must be rated for at least 350 volts. these must lay flat and not touch anything else as they carry high voltage.

| + | |

| − | | + | |

| − | =='''Step 2''' {LEDs and Sockets}==

| + | |

| − | | + | |

| − | Install the Sockets

| + | |

| − | | + | |

| − | <center>[[Image:LEv5-2.jpg|600px|Thumb]]</center>

| + | |

| − | | + | |

| − | *Install the chip sockets in the board in the proper location. Make sure the notch on the one end of the socket is on the same side as the notch in the silk screen on the board. It shows you which way the chips should be inserted.

| + | |

| − | | + | |

| − | *Note* All but the 6 pin IC sockets have bent pins to hold the sockets to the pcb so they don't fall out before soldering.

| + | |

| − | | + | |

| − | Everyone has their own way of holding the socket in until they are soldered in. I like to turn the board over to the back and put the least amount of solder I can over one of the middle holes on one side of the socket. This allows you to put the pins of the other side of the socket through and hold the socket while pushing extremely easy. Then you heat that one hole on the back. When the solder melts the socket will drop in. remove the iron and it will cool and hold the socket in until you are done. Make sure to reheat this pin while doing the others to insure you have a good joint. Some people prefer to use tape to hold them in and some even super glue them on first and then solder. If you use tape then the painter’s masking tape is a good option as it does not leave any residue behind when it is removed. Make sure your socket is in the correct holes and that it faces the correct way and then solder the other pins in. If you are happy with it you can go ahead and start soldering the other sockets in. And check each one for direction before soldering it. Pay careful attention that you are putting the right size socket in the correct set of holes

| + | |

| − | | + | |

| − | Install the Led's

| + | |

| − | | + | |

| − | <center>[[Image:LEv5-3.jpg|600px|Thumb]]</center>

| + | |

| − | | + | |

| − | <center>[[image:LED_polarity.JPG|40px|thumb]]</center>

| + | |

| − | | + | |

| − | *Find the 19 green led’s and install them in their location. They must be inserted in the proper direction for them to work. There will be one lead on the led longer than the other. This is the anode or + side of the led. I used the LED symbol on the board but since there is some confusion to the interpretation of it in the DIY community I added a “+” mark on the correct pad for the anode (long leg) to be inserted into.

| + | |

| − | | + | |

| − | | + | |

| − | Make sure you have this correct. Check before you solder that you are inserting the longer leg into the hole marked “+”.

| + | |

| − | | + | |

| − | | + | |

| − | '''That’s a lot of soldering so take a break.'''

| + | |

| − | | + | |

| − | If you try to do too much in one sitting you will start making too many mistakes and mistakes with solder are costly in time. Notice that we started with fairly short items. It is best to put short items on and work out to the taller items as you go. As you progress you will understand better why this is. The image at the top of this section is what it should look like at this point.

| + | |

| − | | + | |

| − | =='''Step 3''' {Rectifier, Capacitors, Push Buttons, Fuses}==

| + | |

| − | | + | |

| − | | + | |

| − | <center>[[Image:LEv5-4.jpg|600px|Thumb]]</center>

| + | |

| − | | + | |

| − | EXPRESS after step 3

| + | |

| − | | + | |

| − | | + | |

| − | *Now install your rectifier in the location at the top left of the board. It is a black round device and there is a “+” mark on it. Make sure to line this up with the one on the pcb.

| + | |

| − | | + | |

| − | *Install the two 100uf capacitors in their location making sure the black strips that indicate negative are away from the “+” mark on the pcb.

| + | |

| − | [[image:RadialCapacitor_polarity.jpg|60px|center|thumb]]

| + | |

| − | | + | |

| − | *Install the three push buttons. Make sure you look at them and find the small pin on their bottom and align this with the hole for it. This insures the buttons are oriented in the correct direction. The buttons will snap into place and stay for you until you solder them. They are the same part number so it does not matter which goes where.

| + | |

| − | | + | |

| − | *Snap your fuses into the fuse holder clips and make sure the stops which are just bumps to keep the fuse from sliding out are on the outside edge of the unit. Then solder them into the board as shown in the picture.

| + | |

| − | | + | |

| − | =='''Step 4''' {5v and 3.3v Regulators, RJ-45, Headers}==

| + | |

| − | *'''NOTE #1: Double & Triple check that you have one of each a 3.3 volt reg and a 5.0 volt reg (Voltage Regulator) and not one of the 16 Triacs. Please Match up the part numbers in the parts lists to verify BEFORE SOLDERING them in their proper location on the board. They all look the same but they are very different on the inside.'

| + | |

| − | | + | |

| − | <center>[[Image:LEv5-5.jpg|600px|Thumb]]</center>

| + | |

| − | | + | |

| − | | + | |

| − | Put a small amount of heat compound on the regulators if you have it and snap them into the heat sinks making sure to not bend the legs and to get the metal back of the regulator to be in contact with the flat part of the heat sink.

| + | |

| − | | + | |

| − | <center>[[Image:LEv5-6a.jpg|600px|Thumb]]</center>

| + | |

| − | | + | |

| − | *Install the voltage regulators LD33CV and 78s05. The LD33CV is the lower one and the 78s05 is the higher one they both face to the right. Solder the voltage regulators and heat sinks in place.

| + | |

| − | | + | |

| − | *Install the two pin header for the terminate jumper in at the top of the board.

| + | |

| − | | + | |

| − | *Install the two pin header for the RS-485 (enable/disable RS-485 for the wireless modular to work) jumper in at the top of the board.

| + | |

| − | | + | |

| − | *Install the 6 pin ICSP header for reprogramming the pic if needed.

| + | |

| − | | + | |

| − | *Snap the three RJ45 jacks into the board and solder them.

| + | |

| − | | + | |

| − | NOTE: Information on installing headers for use with wireless will be added upon conclusion of the Wireless Beta testing.

| + | |

| − | | + | |

| − | =='''Step 5''' {4700uf Capacitor and Transformer}==

| + | |

| − | | + | |

| − | | + | |

| − | <center>[[Image:LEv5-7.jpg|600px|Thumb]]</center>

| + | |

| − | | + | |

| − | | + | |

| − | *Before Installing the capacitor, install a RS-485 chip between the RJ-45 connector and where the 4700uf capacitor is going in at. Once the Capacitor and Transformer are install it is a tight fit to install the RS-485.

| + | |

| − | | + | |

| − | *Install the large 4700uf capacitor into the board making sure the black strip is on the opposite side away from the “+” on the pcb.

| + | |

| − | | + | |

| − | <center>[[Image:LEV4-9.jpg|600px|Thumb]]</center>

| + | |

| − | | + | |

| − | *Install the transformer in its place. The pins are marked on the transformer 1 – 8 just above the pins themselves. Make sure the #1 pin is in the #1 hole as marked. It is the lower left hole.

| + | |

| − | | + | |

| − | =='''Step 6''' {Triacs, Heatsink, Terminals}==

| + | |

| − | | + | |

| − | *'''NOTE #1: Do not be afraid to turn your irons up really high to solder the triacs middle leg. I do it last and crank my iron from the normal 330 - 340 C to 390 C to do these. Put the iron on the side of the power trace to isolate the lead and solder it.'''

| + | |

| − | | + | |

| − | *'''NOTE #2: Double & Triple check that you have 16 Triacs and not a 3.3 volt reg and a 5.0 volt reg (Voltage Regulator). Please Match up the part numbers in the parts lists to verify BEFORE SOLDERING them in their proper location on the board. They all look the same but they are very different on the inside.'

| + | |

| − | | + | |

| − | <center>[[Image:LEV4-11.jpg|600px|Thumb]]</center>

| + | |

| − | | + | |

| − | Now we need to attach Heat sink to the pcb.

| + | |

| − | * Put a plastic washer on the screw, push screw through the hole and slide a spacer on screw, run the screw into the heat sink just enough to hold. Repeat for other screw and tighten them both up.

| + | |

| − | * Place a drop of heat sink compound on the heat sink between the hole for all of the triacs and the bottom of the heat sink.

| + | |

| − | * Install the 16 triacs with the metal tab towards the heat sink.

| + | |

| − | * Place a screw into hole of each triac and then into heat sink, attach nut and slightly tighten up the screw. Repeat for all triacs. Now fully tighten all screws and nuts.

| + | |

| − | * Solder the triacs to the pcb

| + | |

| − | | + | |

| − | | + | |

| − | <center>[[Image:LEv5-8.jpg|600px|Thumb]]</center>

| + | |

| − | | + | |

| − | | + | |

| − | *Install the connector strips by hooking them together end to end. Then insert them with the holes facing down and solder them into place.

| + | |

| − | *Install the two large power input connectors making sure the large holes are facing down.

| + | |

| − | | + | |

| − | =='''Power Test'''==

| + | |

| − | Time to test your board power BEFORE installing Chips and the PIC. This is a safe way to test the board power before adding in all of the chips.

| + | |

| − | *Make up one power cord for the Express:

| + | |

| − | ** Attach 1 heavy gauge extension cord (14/2) to the LEFT input. The Black is HOT(+), and the White is NEUTRAL(-).

| + | |

| − | | + | |

| − | For your safety temporary place the LE in the case.

| + | |

| − | Now plug in the cord to your outlet and check the two LEDs. Both the 3.3 volt and 5 volt LEDS should be lit.

| + | |

| − | * If both LEDs are lit then all is good at this point. Continue on to Final Assembly

| + | |

| − | * If one or both LEDs are not lit then we need to start checking for the problem.

| + | |

| − | ** Double check that the LEDs are installed correctly.

| + | |

| − | ** Make sure there is power coming in to the LE

| + | |

| − | | + | |

| − | Now later when you add in all of the chips, if any of the power LEDs don't light up the problem is narrowed down to a problem with the chips or PIC.

| + | |

| − | | + | |

| − | *If the 5 volt LED doesn't light up then check the RS-485 chips.

| + | |

| − | | + | |

| − | When done unplug the cord and remove to finish assembly of the Express.

| + | |

| − | | + | |

| − | | + | |

| − | <center>[[Image:LEV4-Fin2.jpg|600px|Thumb]]</center>

| + | |

| − | | + | |

| − | =='''Final Assembly''' {Chips, Case and Electric Cords}==

| + | |

| − | | + | |

| − | | + | |

| − | *Now we need to insert the chips into there correct sockets. The board is marked for the correct part. Get them oriented correctly with pin one in the correct position. Pin one is marked on the chips as a notch on the end where pin 1 is and sometimes a dot over pin one. '''All of the pin # 1 notches or pin #1 dots face different directions so be careful that you get them in the right way'''. Make sure you put chips in very careful and do not bend any pins as they sometimes can be a challenge to insert straight. Take your time here and before pushing them in look over both side to make sure all pins are started straight. Check each chip and be sure its fully in the socket.'''TAKE YOUR TIME HERE!'''

| + | |

| − | | + | |

| − | [[image:Whereis_Pin1_socket.JPG|center|240px|thumb]]

| + | |

| − | [[image:Whereis_Pin1_PIC.JPG|center|90px|thumb]]

| + | |

| − | [[image:Whereis_Pin1.JPG|center|90px|thumb]]

| + | |

| − | | + | |

| − | *Install the three Led display units by plugging them into the 14 pin sockets for them. The decimal point is in the bottom of the display when they are inserted correctly.

| + | |

| − | | + | |

| − | *Install LE into case. Use 4 #8 sheet metal screws 1/2 inch long (not included in the kit)

| + | |

| − | | + | |

| − | *Make up power cords for the Express:

| + | |

| − | ** Using 2 (1 if jumping power together for 20amps only) heavy gauge extension cords (14/2) as the unit can handle large amounts of current so the power input cords must be able to handle it. The Black is HOT(+), and the White is NEUTRAL(-).

| + | |

| − | ** Use 16 normal extension cords (18/2) Cut off the Male end and tin the leads for a solid connection to the screw terminals or SPT2 cable to make the channels power cords.

| + | |

| − | | + | |

| − | The lead wire connected to the larger slot on the plugs should be connect to the channel connector without the “+” next to it. You will find that the wires on the cables normal are ribbed on the “-“side and smooth on the “+” side so make sure and hook up the polarity correct to the board.

| + | |

| − | | + | |

| − | =='''Power Information'''==

| + | |

| − | | + | |

| − | Using both power inputs (ie: two cords on two separate circuits (ie: breakers))

| + | |

| − | 40 amps Total for the Express with approved heat sink attached

| + | |

| − | 4 amps per channel maximum with approved heat sink attached

| + | |

| − |

| + | |

| − | Using one power input (see below - Appendix A single power input mod)

| + | |

| − | 20 amps Total for the Express with approved heat sink attached

| + | |

| − | 4 amps per channel maximum with approved heat sink attached

| + | |

| − | | + | |

| − | | + | |

| − | <center>'''Congratulations you have a finished EXPRESS!'''</center>

| + | |

| − | | + | |

| − | | + | |

| − | Make sure you are not in contact with any part of the EXPRESS and power it up while being ready to disconnect it. If you have no mistakes in the soldering or building, only the LEDS will be lit nothing else should happen it will sit there without doing a thing. This is a good sign (no magic smoke escaped).

| + | |

| − | | + | |

| − | | + | |

| − | Sit back take a deep breath you did it! Pat yourself on the back and have a cold whatever it is you enjoy. When you’re ready you can move on to the operation section and learn how to use it.

| + | |

| − | | + | |

| − | *[[LEv4 Cheat Sheet|LEv4 Cheat Sheet]]

| + | |

| − | | + | |

| − | =='''Programming and Operation of the EXPRESS'''==

| + | |

| − | | + | |

| − | ==='''DMX Cable XLR and or Cat5'''===

| + | |

| − | You will need a DMX dongle on your computer to create DMX. I can only recommend the Lynx DMX Dongle or the Enttec DMX Pro at this time. I have found it to work very well. The DMX open does not have very reliable timing and to try and get stable operation with Vixen K.C. had to add a delay between frames which hurts its update speed. The Lynx or DMX Pro will provide you with perfect DMX all the time and no errors. To wire up your Enttec DMX Pro dongle to the EXPRESS use a XLR end and solder a cat5 cable to it. The pin out should be

| + | |

| − | | + | |

| − | [[image:Lynx and Lor Connections 4.jpg|top|120px|thumb]]

| + | |

| − | | + | |

| − | DMX DONGLE EXPRESS CAT 5 END

| + | |

| − | | + | |

| − | Pin #2 Pin #2

| + | |

| − | | + | |

| − | Pin #3Pin #1

| + | |

| − | | + | |

| − | If using a Lynx Dongle you only need a standard straight through Cat5 cable

| + | |

| − | | + | |

| − | | + | |

| − | That’s it. Once you have your cable ready we need to setup your EXPRESS.

| + | |

| | | | |

| − | To connect another EXPRESS or any other DMX device to this one simply use a standard straight through Cat5 cable to go from the “DMX OUT” jack to the next EXPRESS and connect it to the “DMX IN” jack.

| |

| | | | |

| − | There is a jumper on the board marked “Terminate DMX” This should be on if this is the only DMX device on your string “universe” or the last one. Otherwise if it’s not the last DMX device on the line move it over so it does not connect the two pins and make sure the last device has itself terminated.

| + | You will need a few tools build the LYNX DONGLE. You will need a good soldering iron. I cannot stress enough that a good soldering iron makes a big difference in these projects. The little 15w cheap irons are more apt to hurt your parts by taking too long to get the parts up to soldering temperature than a good iron which can bring it up to temp very fast. Remember, damage is a factor more in how long you keep the part hot than it is how hot you get it (within reasonable soldering temperatures). A good soldering iron is reasonable: You can purchase one for $30 to $60. Most any product that calls itself a soldering station that includes a temperature control separate from the iron itself will more than likely be fine, but make sure it is rated for more than 15 watts. I use a cheap Weller like this one |

| | | | |

| − | [[General_Information_on_Dongle_Connections|More detailed diagrams for XLR to RJ45 connections.]] | + | [http://www.amazon.com/Weller-Soldering-Station-WLC100-120V/dp/B000ICEMYA http://www.amazon.com/Weller-Soldering-Station-WLC100-120V/dp/B000ICEMYA] |

| | | | |

| − | ==='''Programming'''===

| + | It works fine and is very inexpensive. I even saw this model on sale at Sears. Radio Shack has a very nice looking digital model on sale but be careful: it does not allow you to replace the tip. Tips are a part that wear out and need to replace them from time to time. While we are on the topic of tips, get some. I recommend you get the smaller chisel shape as this works very well for all-around board building. |

| − | The EXPRESS first needs to be programmed for its starting channel. This is the channel that #1 output cable will be addressed by in the DMX data. If you want this EXPRESS to handle channels 80 – 95 you would assign it the starting channel of 80.

| + | |

| | | | |

| | | | |

| − | To program it we need to fire up the express and wait for the startup message to finish.

| + | You need solder, so buy some. I recommend .032 size as the larger sizes tend to cause you to put too much solder on. How much? Go ahead and get a 1 lb spool as it’s cheaper in large volume and you will go through it faster than you think. Make sure you are getting rosin core for electronics; they make some solder for plumbing that has acid as the core and this is a bad mistake to make. |

| | | | |

| − | Once this is done it should show the channel it is set to on the display. To change this push the mode button twice. The decimal point should light for the hundreds location on the display. If you wish to change the hundreds just push the edit button until the number is correct. Then push the mode button once to move the decimal to the tens position. Continue this until the address is correct. Once you are done with the ones push the mode button and it should work in on the channel you set. To change channel again you restart the unit and repeat.

| |

| | | | |

| | + | You need some work area to work with good lighting. Do not attempt to solder circuit boards in poorly lighted areas. If you wear reading glasses, go get them: you will want them I promise you. I recommend a set of helping hands like this: [http://www.radioshack.com/product/index.jsp?productId=2104639&cp=&parentPage=search http://www.radioshack.com/product/index.jsp?productId=2104639&cp=&parentPage=search] |

| | | | |

| − | That’s it! It is set to operate on the channel you wanted. You can change it anytime and as often as you need. It will remember the address for at least 20 years with no power applied.

| + | ='''STEP 1'''= |

| | | | |

| | | | |

| − | Being DMX the EXPRESS can be controlled from programs other than Vixen if you so choose. it should work with any DMX devices and I have tested it using a number of downloadable software from the internet including the trial edition of Light Factory that comes with the DMX PRO.

| + | <center>Install the two 100 ohm resistors (291-100-RC [http://ca.mouser.com/Search/include/LargeProductImage.aspx?path=xicon/lrg/643_MFR.jpg]) and .1uf caps (581-SA105E104Z [http://ca.mouser.com/Search/include/LargeProductImage.aspx?path=avx/lrg/LargeAVX-SA-Spinguard.jpg])</center> |

| | | | |

| − | ==='''Lynx Express Configuration Utility'''===

| |

| | | | |

| − | The Express can also have its start address programmed from the windows Configuration Utility program. Along with setting the custom curves for each of the 16 channels.

| + | [[Image:Dongle2-1.jpg|600px|Thumb]] |

| | | | |

| | + | ='''STEP 2'''= |

| | | | |

| − | The [[media:Express-Config.zip]] file that RJ wrote needs to be unzipped and then run the Setup.msi program. This will install the configuration software for the Express on your PC.

| |

| | | | |

| − | Once that is done, click on the Settings menu and then click on Update Light List. This will download the light curves from the DLA website.

| + | <center>Install the two 470 ohm resistors (291-470-RC [http://ca.mouser.com/Search/include/LargeProductImage.aspx?path=xicon/lrg/643_MFR.jpg]). </center> |

| − | [[Image:UpdateCurve2.jpg|600px|Thumb]]

| + | |

| | | | |

| − | A pop up box will display asking if you want to download new light list from DLA - Click on Yes and then OK when its done.

| + | [[Image:Dongle2-2.jpg|600px|Thumb]] |

| | | | |

| − | '''''Below is just some examples showing how to use the program.''''' | + | ='''STEP 3'''= |

| | | | |

| − | *Set the Com port in the Setting menu. Click on Update

| |

| − | [[Image:Comport.JPG|300px|Thumb]]

| |

| | | | |

| | + | Install DIP sockets (571-1-390261-2 [http://ca.mouser.com/Search/include/LargeProductImage.aspx?path=tyco/lrg/pr390261.jpg]), aligning them so the notches on the sockets match those on the board. This indicates the #1 pin end of the socket. |

| | | | |

| − | *Set the start channel from the drop down list.

| |

| | | | |

| − | [[Image:StartChannel.JPG|600px|Thumb]] | + | Next install the pic socket(571-1-390261-9 [http://ca.mouser.com/Search/include/LargeProductImage.aspx?path=tyco/lrg/pr390261.jpg]), making sure the flat metal is on the side with the white solid rectangle of the board. |

| | | | |

| | | | |

| − | *Set the four curves to what you want from the drop down list

| + | Now install the clock chip (520-TCH4000-X [http://www.ecsxtal.com/store/pdf/ECS_2100.pdf]), which is the shiny square. Make sure the small back dot is in the right bottom closest to the white dot on the PCB. |

| − | [[Image:Curves.JPG|600px|Thumb]] | + | |

| | | | |

| | | | |

| − | *Assign the 16 channels to one of the four curves from previous step.

| + | Install the DC to DC isolated power supply (580-MER1S0505SC [http://ca.mouser.com/Search/include/LargeProductImage.aspx?path=murata/lrg/kdc_nmr.jpg]). Make sure that the pin #1 is on the end with the white dot. You cannot install it backwards; due to the pin alignment. |

| − | [[Image:Curve-Channel.JPG|600px|Thumb]] | + | |

| | | | |

| − | * Note Next two steps are swappable.

| |

| | | | |

| − | ** Put your Express in prg mode by hitting the mode button and when "PRG" shows up hit the edit button to turn the decimal on the right on. It should day "PRG."

| + | Install the 100uf capacitor (140-XRL25V100-RC [http://ca.mouser.com/Search/include/LargeProductImage.aspx?path=mousercatalog/lrg/630_593__Radial%20Aluminum%20Electrolytic%20Capacitors.jpg]) and make sure the black strip is on the opposite side from the “+” on the PCB. |

| | | | |

| − | ** Now hit the Program button and the express should program and reboot.

| |

| | | | |

| − | The windows program will stay in transmit mode until you click on the stop button. This allows you to walk around your yard and program all of your Expresses if needed.

| + | Install the Mosfet transistor (512-FQP27P06 [http://ca.mouser.com/Search/include/LargeProductImage.aspx?path=fairchildsemiconductor/lrg/TO220.jpg]). Follow the markings on the silk screen, the metal side faces to the right. |

| | | | |

| − | '''Notes'''

| |

| − | *Make sure a dongle is connected to the computer and Express

| |

| − | *Here is the link to the video of RJ showing the Express being setup with the Config program [[http://diylightanimation.com/index.php?action=dlattach;topic=957.0;attach=750 Video]]

| |

| | | | |

| − | ==='''Flashing or Re-flashing the Express Pic'''===

| + | [[Image:Dongle2-3.jpg|600px|Thumb]] |

| − | The pic used in the Express is a more advance pic that what has been used for other Lynx hardware and most pickit2 programmer extenders (ie: boards with zif sockeks) won't work. Because of this RJ has included a ICSP port on the Express to help ease the process of flashing or re-flashing the pic.

| + | |

| | | | |

| − | If you have a Microchip Pickit2 programmer just plug it in the ICSP port as shown. The triangle is pin #1 and needs to be matched up with pin #1 on the pcb which also has a triangle on it.

| + | ='''STEP 4'''= |

| | | | |

| − | [[Image:pickit-le2.jpg|600px|Thumb]]

| |

| | | | |

| − | or you can use a cable to the ICSP port.

| + | Install the USB module (626-DLP-USB245M-G [http://ca.mouser.com/Search/include/LargeProductImage.aspx?path=mousercatalog/lrg/630_34__USB-UART%20Adapter%20PCB.jpg]) as pictured. '''Do not install a socket''' on this device: it must be soldered to the PCB directly. |

| − | [[Image:pickit-le1.jpg|600px|Thumb]] | + | |

| | | | |

| − | *Once its connected, plug in the Express '''LEFT''' power cable (at the very minimum you should have the 3.3 and 5 volt leds lit, If re-flashing you should have the normal Express startup on the 7-segment LEDs)

| |

| | | | |

| − | *On your computer start up the pickit2 program and check to see if the program has identified the programmer and the pic.

| + | Solder the RJ45 jack (571-5202514 [http://ca.mouser.com/Search/include/LargeProductImage.aspx?path=tyco/lrg/pr2619006b.jpg]) in place. (Shown in the next picture.) |

| | | | |

| − | <center>[[Image:pickit2-1.jpg]]</center>

| |

| | | | |

| − | *Click on ERASE button and then BLANK CHECK button (not really needed but just a good habit to follow).

| + | '''MAKE SURE BOTH OF THESE ARE FLAT AND TIGHT AGAINST THE PCB WHEN YOU SOLDER IT.''' |

| | | | |

| − | *Load in the firmware for the Express [http://diylightanimation.com/wiki/index.php?title=Equipment#Dimmers Latest Firmware]

| + | [[Image:Dongle2-4.jpg|600px|Thumb]] |

| − | <center>[[Image:pickit2-2.jpg]]</center>

| + | |

| | | | |

| − | *Click on the WRITE button (sends the firmware to the pic)

| + | ='''STEP 5'''= |

| | | | |

| − | <center>[[Image:pickit2-3.jpg]]</center>

| + | Install the three chips making sure to take your time and not bend the pins. The notches on the chips should be on the same end as the notches on the sockets. |

| | | | |

| − | *Click on VERIFY button

| + | Referencing the picture in Step 1 to insert the RS485 chip (511-ST485BN [http://ca.mouser.com/Search/include/LargeProductImage.aspx?path=stmicroelectronics/lrg/dip-8.jpg]) in the socket on the left-hand side. The Optocoupler chip (630-6N137-000E [http://ca.mouser.com/Search/ProductDetail.aspx?qs=sGAEpiMZZMs50KUSuyRkpmqwble0%2fe0HPRu7R4B4k9U%3d]) will insert in the right-hand side socket. |

| | | | |

| − | <center>[[Image:pickit2-4.jpg]]</center>

| |

| | | | |

| − | The above was tested with the following version of Pickit2 program

| + | Download the Hex file from the forum and program the PIC chip (579-PIC18F2450-I/SP [http://ca.mouser.com/Search/include/LargeProductImage.aspx?path=microchiptechnology/lrg/28-PDIP-Narrow-2-300dpi-lyrd.jpg]) with it using whatever steps are correct with your programmer. |

| − | [[Image:pickit2-5.jpg]]

| + | |

| | | | |

| − | Note:

| + | Check out this post for a helpful .pdf: http://diylightanimation.com/index.php?topic=1395.msg14012#msg14012 |

| − | Some things I ran into:

| + | |

| − | *At first I could not write to the pic, I was able to do all of the other functions. Turns out it was my usb port on my computer. Once I tried it on another computer there was no problem. Note: first computer was using ver2.60

| + | |

| − | *pic not identify - click on pic24 from the device family menu

| + | |

| − | *no pic founded - if using a cable to the ICSP port, reverse the connection. There is a triangle where the pin #1.

| + | |

| | | | |

| − | ----

| + | Some helpful tips: http://www.youtube.com/watch?v=EOWWKPPilI0 |

| | | | |

| | | | |

| − | '''REMEMBER ALWAYS HAVE IT UNPLUGGED WHEN WORKING WITH IT. THERE IS LINE POWER ON THE BOARD AT ALL TIMES IT IS PLUGGED IN AND THE OUTLETS HAVE POWER AT THEM. BE SAFE!''' | + | '''They are not all facing the same way.''' |

| | | | |

| − | <center>'''Thank you, enjoy your EXPRESS RJ'''</center>

| + | Make the two square holes in the case and mount the PCB into it. |

| | + | *[[media: LynxDonglePattern-Ruler.pdf]] |

| | + | *[[media: LynxDonglePattern-Micrometer.pdf]] |

| | | | |

| − | ----

| |

| | | | |

| − | =='''Appendix A single power input mod'''==

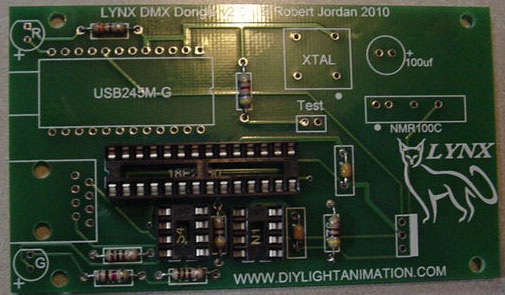

| + | [[Image:Dongle2-5.jpg|600px|Thumb]] |

| | | | |

| − | If you would like to mod your Express to use a single power input cable you must limit your output current to 20 amps or less.

| + | ='''STEP 6'''= |

| | | | |

| − | This is a simple mod and requires only two short jumpers of SPT2 lampd cord from an old extenstion cord ect.

| |

| | | | |

| − | make sure your jumper can handle 10 amps or more.

| + | Screw the top on and flip the case over to the smooth side and attach the sticker. |

| | | | |

| − | Turn the PCB over so you are looking at this :

| |

| | | | |

| − | [[Image:Appendix a.jpg]] | + | [[Image:Dongle-1.jpg|600px|Thumb]] |

| | | | |

| − | Now where I have drawn the two red jumpers in just jumper these with the jumpers by soldering them in to the bottom with them tight against the bottom and cut the part sticking above the pcb on the top where you solder them off flush with the pcb. The jumpers are on the bottom of the board not on the top. you will solder these on the top and cut them off flush.

| |

| − |

| |

| | | | |

| − | '''Once you have done this do not attach the right Power input connector during the build. Only use the left one(near transformer). This is important for safety.'''

| + | Congrats! You have a DMX dongle. To download drivers go to [http://www.ftdichip.com/Drivers/VCP.htm http://www.ftdichip.com/Drivers/VCP.htm] |

| | | | |

| − | Once you do this continue on with the rest of the build.

| + | and download and run [http://www.ftdichip.com/Drivers/CDM/CDM%202.04.16.exe http://www.ftdichip.com/Drivers/CDM/CDM%202.04.16.exe] |

| | | | |

| | | | |

| − | =='''Appendix B 240VAC mod'''==

| + | '''Do not plug in the dongle until you have the drivers installed.''' |

| | | | |

| − | The Lynx Express can be modified for 240VAC operation in three easy steps: Cut two traces, add a jumper, and substitute 16 resistors.

| |

| | | | |

| − | First you'll need 16 1/4W 5% Carbon Film Resistors 330 Ohm. The Mouser part number is 660-

| + | Now plug the dongle into a USB port on your computer using a USB cable and it should be found and installed as a comm port. |

| − | CF1/4C331J. These will replace 16 of the 32 180 ohm resistors (291-180-RC) in the standard BOM.

| + | |

| | | | |

| − | Locate the Transformer area on the top (printed) side of the LE pcb. In the picture below the red arrow points to the rectangle marked "120 v."

| |

| | | | |

| − | [[Image:LE_240V_Mod.jpg]]

| + | Go into Vixen and open a new sequence. Set up using the ENTTEC DMX PRO plug-in and assign it to the comm port the dongle created. Set the comm speed to 115K and exit the plug-in setup. |

| | | | |

| − | Flip the board over to the back (unprinted) side. Using a sharp tool or rotary cutting blade, cut the two traces between the 120 v holes along the black line indicated by the red arrow in this picture:

| |

| | | | |

| − | [[Image:LE_Trace_Cut_Jumper.jpg]]

| + | Now create some stuff and run it. You should have DMX coming out of the dongle. It’s that simple or so we hope. |

| | | | |

| − | Now add a jumper wire between the two holes under the "240 v" rectangle, indicated by the black arrow and red line in the picture above. Solder the jumper on the back of the board and then cut off flush any excess on the top side. You don't want anything to interfere with installation of the transformer in a later step. When finished, the back of the board should look something like this:

| |

| | | | |

| − | [[Image:LE_Trace_Jumper_done.jpg]]

| + | I truly hope you enjoy your LYNX DMX DONGLE. |

| | | | |

| − | Now install the 16 330 Ohm Resistors. Solder these in place of the 180 Ohm Resistors '''''without the dot''''' printed on the top of the board. Note the location marked by the yellow arrow in the first picture above. Every other resistor will be a 330 Ohm beginning with the first, alternating with the 180 Ohm ones with a dot in that row.

| |

| | | | |

| − | Complete the build of your LE per the normal instructions above. When complete, your LE is ready to be powered by and control 240VAC lights.

| + | <center>'''RJ'''</center> |

| | | | |

| | | | |

Thank you for making the decision to build the LYNX DMX DONGLE. I believe this decision will be one you will be very happy with. The Lynx is my attempt to design the best DMX dongle I could, at the lowest price I could, and make it available for the do-it-yourselfers like you. The goals for the dongle were professional looks and operation, cost effectiveness and ease of assembly for even a novice builder.

The next thing we want is to make sure you are up to speed on soldering and electrostatic protection of the components in your kit. If you are not an experienced printed circuit builder, visit the site: http://curiousinventor.com/guides/How_To_Solder

And check out there extremely good video on soldering correctly. Even if you are an expert it is a good video to watch.

It works fine and is very inexpensive. I even saw this model on sale at Sears. Radio Shack has a very nice looking digital model on sale but be careful: it does not allow you to replace the tip. Tips are a part that wear out and need to replace them from time to time. While we are on the topic of tips, get some. I recommend you get the smaller chisel shape as this works very well for all-around board building.

Install the three chips making sure to take your time and not bend the pins. The notches on the chips should be on the same end as the notches on the sockets.

Make the two square holes in the case and mount the PCB into it.

Screw the top on and flip the case over to the smooth side and attach the sticker.